Making sulphite-free wines – in the strictest sense of the term – is a goal winemakers increasingly strive towards, but it requires a lot of mastery, as well as common sense and good winemaking practices. However, at times, no matter how many precautions have been taken, the total elimination of sulphites is impossible due to problems of various kinds (costs, constraints, timing, etc.). Sulphites, thanks to their antioxidant and antiseptic properties, help produce brisk, clean wines. What you can do is reduce your use of them during the processing phases, by combining different winemaking practices and products based on the specific problems to be solved.

Perdomini-IOC actively pursues a policy of sulphite reduction through research programmes for the development of specific winemaking protocols focused on preserving consumer health. This is how the products in the Low SO2 Solutions range were born.

THE MICROBIOLOGY OF GRAPES AND MUST

Winemaking with little SO2 requires total control of oxygen levels and hygiene from the earliest stages of the harvest. Harvesting healthy grapes is a prerequisite for working without or with minimum doses of sulphites. With Botrytis (and therefore laccase) on the grapes, musts and wines are very sensitive to oxidation. Without sulphites, wines maintain significant polyphenol-oxidase activity and can easily deteriorate. It is therefore essential to preserve the integrity of the grapes during the harvest and up to their arrival in the winery. If this does not happen, unwanted bacteria and yeasts will have free access to sugars be able to multiply exponentially, causing major damage.

However, a healthy grape is not free from microorganisms. It is now known that on the skin there may be a significant population of Hanseniaspora uvarum-type apiculate yeasts able to produce volatile acidity. These yeasts can easily dominate the pre-fermentation stages and affect aromatic fineness when the wine is racked if there is not adequate protection in place. In order to avoid the onset of these problems, the temperature during racking (which must not exceed 8-10°C) and the length of time on the lees (the longer this is, the more risks arise) both play a fundamental role.

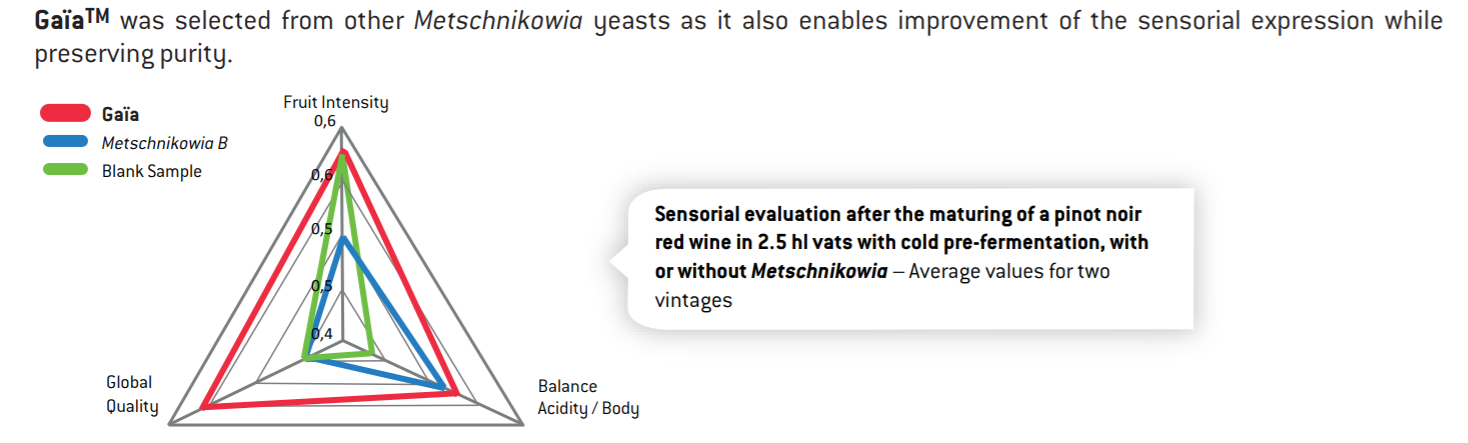

A proven solution in these situations, as an alternative to sulphites, is the use of a bioprotective yeast that can inhibit the growth of these undesirable substances. For example, to govern H. uvarum, the Institut Francais de la Vigne et du Vin has selected GAÏA, a Mestchnikowia fructicola yeast, which is particularly effective at controlling unwanted flora. In addition to delaying the start of unwanted fermentation by occupying an ecological niche used by other microorganisms, GAÏA considerably restricts the growth of acetic bacteria in the must and is an entirely natural solution.

Nevertheless, be cautious. A fundamental aspect of bioprotection is acting in advance, because once unwanted populations have become settled, it is much more difficult to counteract them. We therefore recommend adding GAÏA (after rehydrating it) directly into the grape bins, spreading it as evenly as possible.

USING FERMENTATION AS AN ALLY IN SULPHITE REDUCTION

The concentration of sulphites in the wine is tied to the additions made during the various stages of winemaking. The only stage of winemaking in which an uncontrolled increase can occur by endogenous means is alcoholic fermentation.

Classic winemaking yeasts and – even more so – certain indigenous yeasts can generate variable, even high quantities (in the range of 40-100 mg/l) of SO2. These same yeasts generally produce significant concentrations of acetaldehyde, which combines easily with sulphites. This capacity depends on the temperature, turbidity and nutrient conditions in the must. However, some rare yeasts do not have this property to produce SO2, whatever the fermentation environment. Some innovative selection methods have recently made it possible to obtain this type of yeast for winemaking: the IOC BE range. IOC BE THIOLS and IOC BE FRUITS are more effective than the traditional low-SO2/acetaldehyde yeasts (IOC TwICE, IOC R 9008, IOC PrimRouge, etc.) on the market.

Bio-controlling the fermentation process using the specially selected IOC BE yeasts allows winemakers to avoid the unplanned production of endogenous SO2 and acetaldehyde, leading to greater overall control.

OPTIMIZING THE ANTIOXIDANT POTENTIAL OF MUSTS AND WINES

Reduced glutathione (GSH) is a tripeptide that indirectly displays strong antioxidant abilities. For decades, it has been recognized as a powerful natural antioxidant because it reacts with quinones and stops their agglomeration (the cause of darkening in musts and oxidized wines) and the oxidation of aromatic compounds. It is naturally present in both grapes and yeast, but often in too small quantities to be able to protect the wine effectively. To counteract this problem, special inactivated, glutathione-rich yeasts can be used to reduce the vulnerability of musts and wines to oxidation.

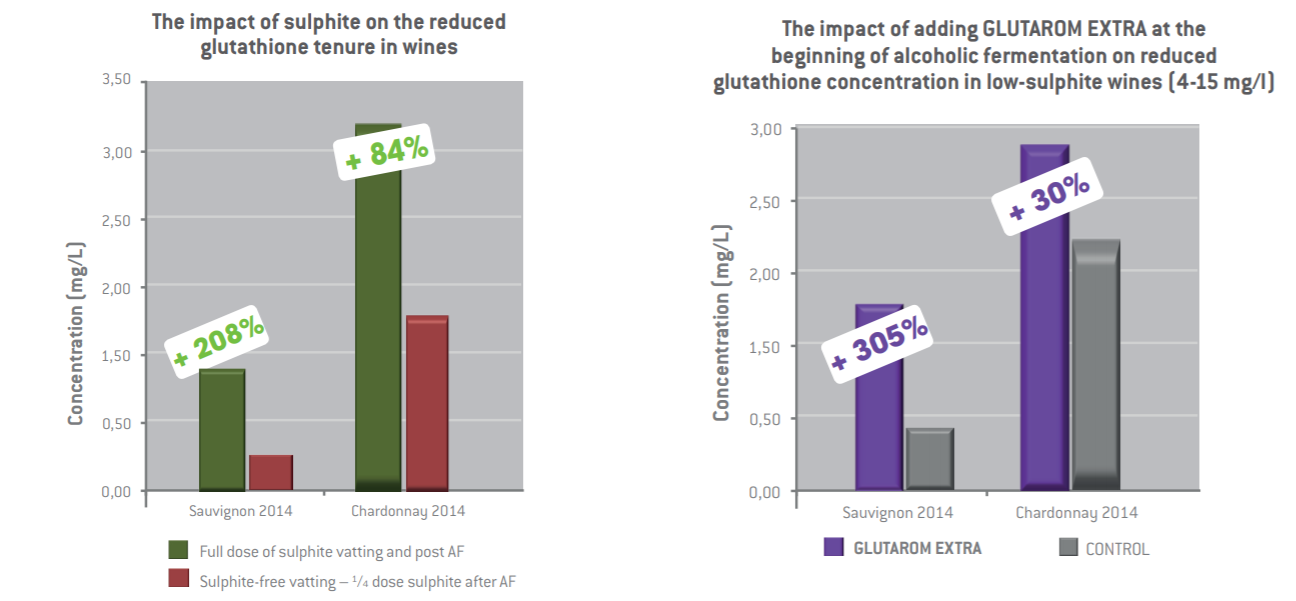

GLUTAROM EXTRA is a nutrient resulting from the latest techniques for selecting and producing inactivated yeasts with very high GSH content. When added at the beginning of fermentation, it leads to a wine with a higher concentration of GSH, but it is essential to feed the yeast the right amount of organic nitrogen. When the sulphite content is low, the positive impact generated by the high GSH concentration on aromas is crystal clear, even in red wines. In addition, it has been shown that the addition of GSH-rich inactivated yeast is more effective on the aromatic content than the addition of pure glutathione, most likely due to synergies with the nutritional effect of other yeast derivatives.

Through our experiments, we have been able to verify the positive effect of GLUTAROM EXTRA used at the beginning of fermentation on the active glutathione content of low-sulphur wines (addition of 0.4-1.5 g/hl of SO2 post-fermentation). These levels are much higher than those in the same wines without the addition of GLUTAROM EXTRA. Moreover, they are similar to or higher than those in wines with full-dose sulphites (addition of 5-10 g/hl of SO2). In conclusion, low-sulphite wines to which GLUTAROM EXTRA has been added show better resistance to air, even when GLUTAROM EXTRA is no longer in contact with the wine.

GOVERNING BACTERIA FOR MLF

The question of malolactic fermentation now arises. The use of selected yeasts makes it possible to control this stage and avoid masking the fruitiness of the wines with too many buttery notes and also, by consuming the residual acetaldehyde, limit loss of aromas and oxidation. Even if MLF is not desirable at a high pH, it is often preferable to trigger it with skill rather than allow a spontaneous start that would be difficult to govern without the use of sulphites, thus increasing the risk of damaging the sensory profile of the wine.

For strict microbiological control without the use of sulphur dioxide, using Sentinel makes it possible to reduce the bacterial load (lactic and acetic) and to help stop MLF if it is not desired, or to stabilise the wine when MLF is finished. Sentinel is a product made from chitin derivatives; numerous studies have confirmed their inhibiting effect. Their electrostatic charge allows them to adhere to cell walls and the effect can be most clearly seen on the bacterial population.

OXYGEN, WINEMAKERS’ ENEMY NO. 1

O2 is a fundamental component behind oxidation mechanisms and remains the main obstacle to the production of sulphite-free wines. To limit O2 consumption, the must or wine can be cooled. This solution is apparently effective but insufficient, as it would make it more soluble. Slight deliberate oxidation of the must also has the purpose of precipitating unstable phenolic compounds, in order to obtain more stable wines. However, our experience shows that with this practice the resulting wines are less refined and elegant. The antioxidant effect of sulphur dioxide is the most difficult effect to replicate with other winemaking products.

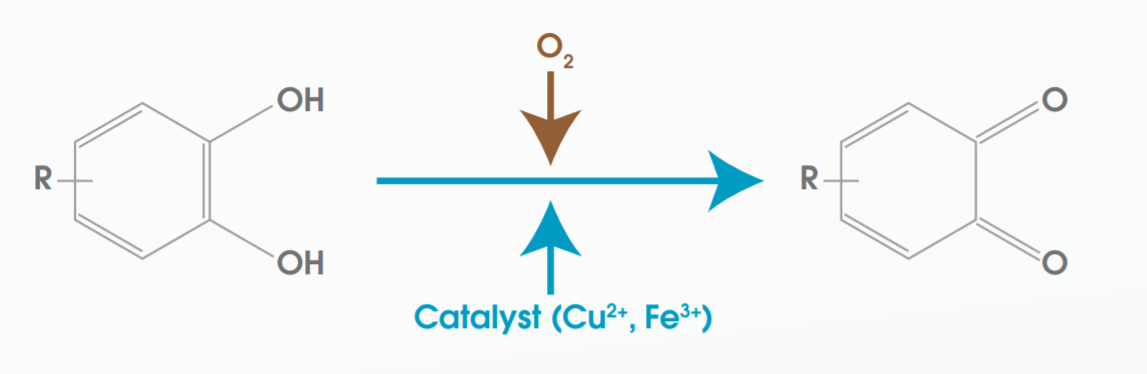

However, oxidation processes are characterized by three factors: an oxidizable substrate, an oxidizer (O2) and a catalyst. By acting on the substrate and catalyst as well as governing the oxygen, the likelihood of premature oxidation can be reduced.

For red wines, Qi FINE is very effective thanks to its absorption of the polyphenol compounds that contribute to the oxidation process. This formulation is suitable for clarifying the must and/or wine and, if used for the fining of wines and red musts during racking or alcoholic fermentation, it becomes an ideal tool in the particular case of polyphenol-rich musts, such as musts obtained by pressing or using pellicular maceration.

For red wines, Qi FINE is very effective thanks to its absorption of the polyphenol compounds that contribute to the oxidation process. This formulation is suitable for clarifying the must and/or wine and, if used for the fining of wines and red musts during racking or alcoholic fermentation, it becomes an ideal tool in the particular case of polyphenol-rich musts, such as musts obtained by pressing or using pellicular maceration.

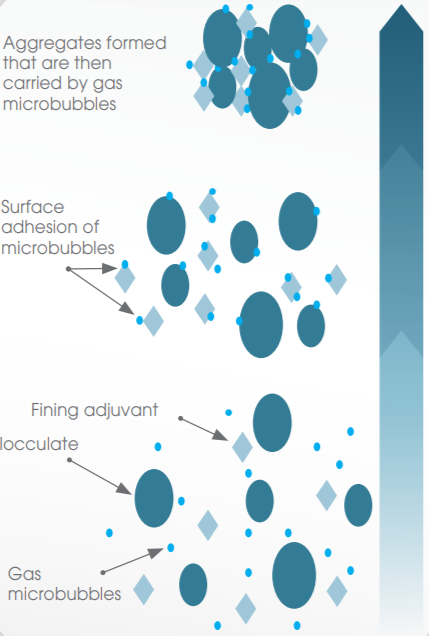

In white and rosé wines, racking by means of nitrogen flotation allows musts to be deoxygenated, an operation that limits oxidation reactions by eliminating the substrates – ortho-diphenols –, which in their oxidized form are yellowish-brown. Qi UP is an additive free from GMOs, allergens and synthetic ingredients; it’s of 100% non-animal origin and makes wine healthier all round. Its effectiveness and speed of action allow it to trigger flotation in any type of must, while preserving the sensory qualities of the initial product.

As far as catalysts are concerned, the main ones in winemaking are metal ions, especially iron and copper ions.

These oxidative reactions contribute to the formation of derivatives that play a role in decreasing fruity or floral notes and drawing out other, heavier notes (honey, jam, Madeira, etc.). At the same time, there is also an undesirable evolution of colour towards orange tinges.

Qi TRAPPING makes it possible to prevent the defects caused by overly high iron and copper contents, which can cause iron or copper precipitation and also premature oxidation of wines. It’s a unique and innovative technological additive composed of polysaccharides of non-animal origin, and is totally free from allergens and synthetic ingredients.

The combination of these techniques and products (and other aids) can help winemakers come closer to their goal of producing sulphite-free or low-sulphite wines without compromising on quality. The Low SO2 Solutions protocol and the Qi range are produced and developed entirely by the IOC group.